The 4th Industrial Revolution or Industry 4.0 is a term describing the most recent trends from the industrial landscape. The digitalization of the manufacturing process is taken one step further through the introduction of cyber physical systems in the production shop floors. These are smart systems which are not only capable to monitor the physical processes but can also support real-time communication between them and even take decisions autonomously.

The development of smarter edge devices which are part of the so called “Internet of Things – IoT” or “Industrial Internet of Things – IIoT” plays a significant role in making entire production lines smarter.

By combining the already existing industrial automation with such innovative devices a higher level of awareness and understanding of the issues within the shop floor can be achieved. This enables a proactive attitude which can significantly improve operational efficiency and productivity by maximising the asset utilisation rates and reducing downtime. Moreover, it can facilitate the identification and creation of new business opportunities.

An intelligent or smart factory is a term which characterises a production plant where adaptability, resource efficiency, and ergonomics are at the core of day to day business. These concepts can be ensured through a network of interconnected cyber physical systems, edge devices, software systems and software platforms.

All these components integrate seamlessly in order to support the decision making process. In the long run, the decision process could eventually even take place autonomously by employing Artificial Intelligence and utilising Machine Learning algorithms capable to identify anomalies or malfunctions in the production line and learn to prevent them by adopting a proactive asset maintenance process.

The implementation of the smart factory extends usually behind the four walls of the factory and ensures the integration of customers and partners in the business and value processes.

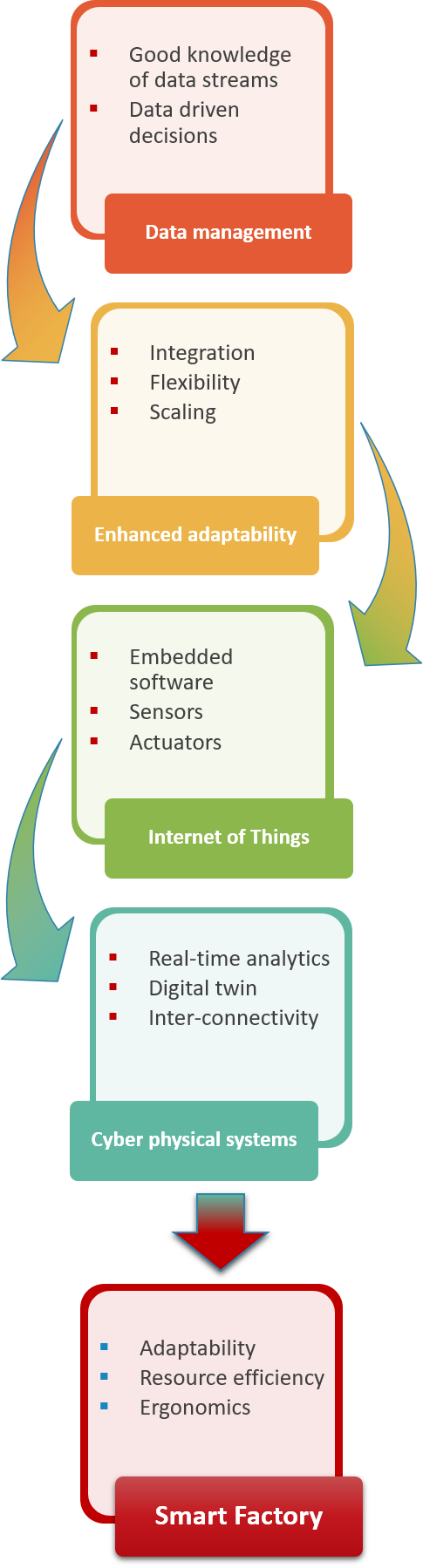

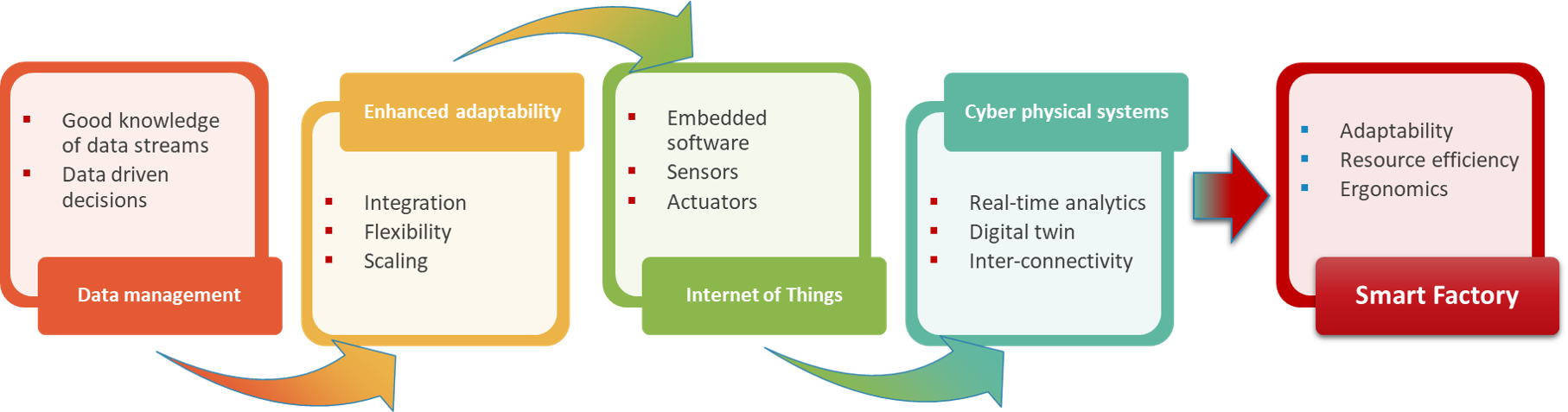

We have identified 4 key areas of focus for turning the smart factory concept into reality and have developed a stepped approach towards this goal. We consider these to be the cornerstone for each organisation operating in the industrial manufacturing area wishing to adopt the smart factory concept in order to make the most out of the newest technological developments. Highlights of these steps are illustrated below:

Towards our goal of making factories smarter and taking an active part in the 4th Industrial Revolution, the following turn-key solutions from our portfolio pave the way and can reduce implementation time: